At what Resolution Should Precision

Agriculture Operate?

At what Resolution Should Precision

Agriculture Operate?As a result of this vision, team members in

soil science began to embark on answering that specific question.

First,

this

group identified visually homogenous areas and took 8 soil cores from

each 1x1 ft area within a 490 ft2 grid at two locations. These

results were later published in the

Soil Science Society of America Journal (62:683-690). This

work clearly showed that significant differences in soil test properties

(Mehlich III-P, organic carbon, total nitrogen, NH4-N, and NO3-N)

existed at distances less than 3 feet apart

this

group identified visually homogenous areas and took 8 soil cores from

each 1x1 ft area within a 490 ft2 grid at two locations. These

results were later published in the

Soil Science Society of America Journal (62:683-690). This

work clearly showed that significant differences in soil test properties

(Mehlich III-P, organic carbon, total nitrogen, NH4-N, and NO3-N)

existed at distances less than 3 feet apart .

This was an alarming finding, considering early 1990's research thrusts

in the grid sampling arena. If you shift the sampling point

(center or corner of each grid) for a grid based system 3-10 feet away,

would it result in an entirely different contour map? The answer

to that was clearly yes. Ensuing work by

Solie et al.1999

showed that in

order to describe the variability encountered in the field experiments,

soil, plant and indirect measurements should be made at the meter or

submeter level.

.

This was an alarming finding, considering early 1990's research thrusts

in the grid sampling arena. If you shift the sampling point

(center or corner of each grid) for a grid based system 3-10 feet away,

would it result in an entirely different contour map? The answer

to that was clearly yes. Ensuing work by

Solie et al.1999

showed that in

order to describe the variability encountered in the field experiments,

soil, plant and indirect measurements should be made at the meter or

submeter level.

Once these fundamental

questions had been answered, another trial was initiated to demonstrate

the benefits of operating at a 0.84m2 spatial scale

(J. Plant Nutr.

24:313-325). In

the second year of the experiment, there was a trend for a lower N rate

and a higher efficiency of use for the 0.84 m2

resolution. Although this study was inconclusive it was a step in

the right direction in terms of experimental design and rigor required

to evaluate the importance of spatial scales.

Once these fundamental

questions had been answered, another trial was initiated to demonstrate

the benefits of operating at a 0.84m2 spatial scale

(J. Plant Nutr.

24:313-325). In

the second year of the experiment, there was a trend for a lower N rate

and a higher efficiency of use for the 0.84 m2

resolution. Although this study was inconclusive it was a step in

the right direction in terms of experimental design and rigor required

to evaluate the importance of spatial scales.

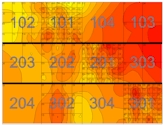

To

some extent this study was unsuccessful in demonstrating the benefits of

operating at a resolution of 0.84m2 and smaller, simply because we did

not have the appropriate Nitrogen Fertilization Optimization Algorithm

(NFOA) in place. However, contour plots from each of the

experiments conducted by Ms. Joanne LaRuffa, clearly showed that

differences existed at resolutions much smaller than 0.84m2.

Contour plots were generated using one of the more advanced hand-held

optical sensors developed by Dr. Marvin Stone and Dr. John Solie (image

to the right, with 0.84m2 plots).

To

some extent this study was unsuccessful in demonstrating the benefits of

operating at a resolution of 0.84m2 and smaller, simply because we did

not have the appropriate Nitrogen Fertilization Optimization Algorithm

(NFOA) in place. However, contour plots from each of the

experiments conducted by Ms. Joanne LaRuffa, clearly showed that

differences existed at resolutions much smaller than 0.84m2.

Contour plots were generated using one of the more advanced hand-held

optical sensors developed by Dr. Marvin Stone and Dr. John Solie (image

to the right, with 0.84m2 plots).

That

significant differences in biomass and N fertilizer need exist at

resolutions less than 0.84m2 is undisputed. We simply have too

many examples where differences in nutrient need at scales as small as 7

inches or 0.18m exist in wheat producer fields. Even in some of our

long-term soil fertility experiments that have been managed the same way

for over 30 years, we find significant differences in biomass and grain

yield production over distances less than 1.0m2.

That

significant differences in biomass and N fertilizer need exist at

resolutions less than 0.84m2 is undisputed. We simply have too

many examples where differences in nutrient need at scales as small as 7

inches or 0.18m exist in wheat producer fields. Even in some of our

long-term soil fertility experiments that have been managed the same way

for over 30 years, we find significant differences in biomass and grain

yield production over distances less than 1.0m2.

How

could such large differences (within plots) be found in a long-term

experiment where management, and fertilization practices had been

exactly the same for 30 years? One thing that was clear from our

microvariability work was that

significant differences in soil texture also existed at scales < 1.0m2.

If texture differences were different, moisture holding capacity would

also be affected and that would likely be visible in plant growth when

moisture was limiting.

How

could such large differences (within plots) be found in a long-term

experiment where management, and fertilization practices had been

exactly the same for 30 years? One thing that was clear from our

microvariability work was that

significant differences in soil texture also existed at scales < 1.0m2.

If texture differences were different, moisture holding capacity would

also be affected and that would likely be visible in plant growth when

moisture was limiting.

Who

can argue that the demands for fertilizer in the examples that follow

are profoundly different,

Who

can argue that the demands for fertilizer in the examples that follow

are profoundly different,

by-row

(both wheat and corn)? Is the 'environmental approach' going to

fertilize each of these rows with the exact same rate, even though need

was entirely different. Is our approach to maximize yields going

to fertilize each of these rows with the same rate even though we

clearly know that one may require 50 kg less N? When corn plants

emerge 3 to 7 days later in a monoculture, these plants can become weeds

because they compete for moisture and nutrients with those plants that

will produce a significant amount of grain. Should we fertilize

each of

by-row

(both wheat and corn)? Is the 'environmental approach' going to

fertilize each of these rows with the exact same rate, even though need

was entirely different. Is our approach to maximize yields going

to fertilize each of these rows with the same rate even though we

clearly know that one may require 50 kg less N? When corn plants

emerge 3 to 7 days later in a monoculture, these plants can become weeds

because they compete for moisture and nutrients with those plants that

will produce a significant amount of grain. Should we fertilize

each of

these

plants with the same N rate? Our goal must be to recognize the

scale where we know differences exist. In corn, it is clearly by

row, and by plant.

these

plants with the same N rate? Our goal must be to recognize the

scale where we know differences exist. In corn, it is clearly by

row, and by plant.

If

a system is developed that senses every 2 rows and applies a rate based

on the average, we sacrifice the savings in fertilizer N that we know

exists at that scale and the yield potential that won't be achieved

because we averaged rates for those rows/plants that clearly required

different amounts. The environmental implications and/or

consequences of misapplied N fertilizer are not considered here, but an

appropriate value must be placed on the scale which will deliver

'precision N placement' in agricultural fields.

If

a system is developed that senses every 2 rows and applies a rate based

on the average, we sacrifice the savings in fertilizer N that we know

exists at that scale and the yield potential that won't be achieved

because we averaged rates for those rows/plants that clearly required

different amounts. The environmental implications and/or

consequences of misapplied N fertilizer are not considered here, but an

appropriate value must be placed on the scale which will deliver

'precision N placement' in agricultural fields.

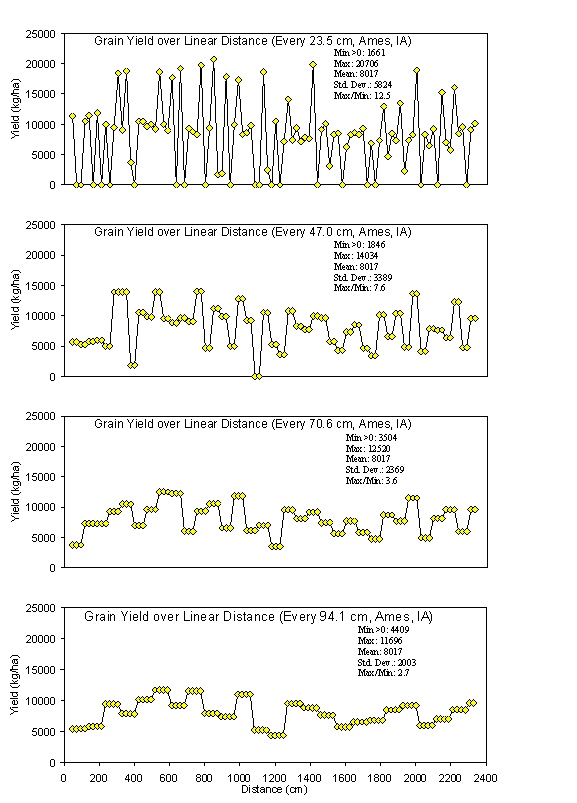

Early

on, our project focused on predicting yield potential from sensor

readings taken at early stages of growth. Implicit in this work

was the scale at which readings would have to be taken. As a result we

recognized that each 1m2 area had to be sensed independently and that

yield would need to be determined from that same 1m2 area. From

1998 to 2002, we compiled data from 28 locations over this 5-year period

and developed an index (In-Season-Estimated-Yield or

INSEY) capable of predicting yield potential using in-season optical

sensor based measurements. This INSEY index has now been

significantly modified from earlier versions, however, one thing remains

the same and that is the resolution or scale at which sensor

measurements were taken and the ensuing grain yield. Would we have

been able to demonstrate this relationship using a resolution of 10m2?

This is highly unlikely considering the variability that we have

encountered in agricultural fields.

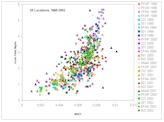

Early

on, our project focused on predicting yield potential from sensor

readings taken at early stages of growth. Implicit in this work

was the scale at which readings would have to be taken. As a result we

recognized that each 1m2 area had to be sensed independently and that

yield would need to be determined from that same 1m2 area. From

1998 to 2002, we compiled data from 28 locations over this 5-year period

and developed an index (In-Season-Estimated-Yield or

INSEY) capable of predicting yield potential using in-season optical

sensor based measurements. This INSEY index has now been

significantly modified from earlier versions, however, one thing remains

the same and that is the resolution or scale at which sensor

measurements were taken and the ensuing grain yield. Would we have

been able to demonstrate this relationship using a resolution of 10m2?

This is highly unlikely considering the variability that we have

encountered in agricultural fields.

Most recent efforts have focused on the

evaluation of a Field-Scale-Variable-N-Rate-Applicator developed jointly by Oklahoma State University and

NTech Industries.

Recognizing a problem area in Hennessey where there simply was no wheat

was important (traveling vertically across a horizontal area where no

wheat grew due to excessive moisture/ponding). In several cases we

found that the sensor could miss by as much as 6 to 12 inches.

What if we had been traveling the other direction (parallel with the

problem) using a resolution of 10m2? Would we recognize the areas

where there was no wheat? Based on averages, we would just

fertilize the bare soil and the growing wheat with the same rate.

This would really be environmentally sensitive!

jointly by Oklahoma State University and

NTech Industries.

Recognizing a problem area in Hennessey where there simply was no wheat

was important (traveling vertically across a horizontal area where no

wheat grew due to excessive moisture/ponding). In several cases we

found that the sensor could miss by as much as 6 to 12 inches.

What if we had been traveling the other direction (parallel with the

problem) using a resolution of 10m2? Would we recognize the areas

where there was no wheat? Based on averages, we would just

fertilize the bare soil and the growing wheat with the same rate.

This would really be environmentally sensitive!

Has our project clearly demonstrated that there are economic benefits of working at the 0.4 to 1.0m2 resolution? Recent results demonstrated that averaged over 4 locations, NUE was improved by >15% when N fertilization was based on optically sensed INSEY, determined for each 1m2 area and a Response Index compared to traditional practices at uniform N rates (Agron J. 94:815-820). This same work showed that VRT treatment at the 1m2 resolution versus flat N rates (common practice employed today) resulted in revenue gains approaching 30$/ha. Did we evaluate VRT at a scale of 2.0m2? No. Why? Because we matched the scale at which we knew we could detect differences in yield potential and that would be the same scale where different nutrient needs would be present. This part of what we have done is quite simple.

Our recent Field-Scale VRT experiments clearly showed the economic benefits of sensing and treating at the 0.4m2 scale versus flat rates. At those sites where the total preplant and topdress rates were similar (VRT vs VS2), the VRT treatment resulted in a net gain of $12.00 per acre. We do not have a 2.0m2 resolution VRT treatment to compare this to. However, all of the research that we have conducted over the years documents the need to operate at a scale finer than 1.0m2 and one that should not be compromised.

All of the 10 field-scale VRT trials that

our team put out this past year had demonstrated spatial scale

differences at the 1.0m2 resolution.

We

know that and we have known this for a long time. If our group

decides to develop an applicator that works at a much coarser scale than

the one where we know differences in need exist and where differences in

resultant yield potential exist, it is because we chose to bury our

heads in the sand, not because we didn't have the scientific information

available.

We

know that and we have known this for a long time. If our group

decides to develop an applicator that works at a much coarser scale than

the one where we know differences in need exist and where differences in

resultant yield potential exist, it is because we chose to bury our

heads in the sand, not because we didn't have the scientific information

available.

Our most recent results in corn demonstrate

the

repeatable by-plant differences sensed with the

GreenSeeker

hand-held unit that is now commercially available via NTech

Industries.

Finding

repeatable NDVI readings ranging from 0.4 to 0.9 within the same row

demonstrates that not only does the variability exist, but that we can

recognize it! Should we now chose to ignore it? If these

differences can be recognized within row, the by-row differences (left

and right) are a must for variable N rate application.

Finding

repeatable NDVI readings ranging from 0.4 to 0.9 within the same row

demonstrates that not only does the variability exist, but that we can

recognize it! Should we now chose to ignore it? If these

differences can be recognized within row, the by-row differences (left

and right) are a must for variable N rate application.

Our field-scale applicator clearly demonstrated the economic benefits of operating at the 0.4m2 scale (in spite of many agronomic and engineering problems encountered during the winter of 2002). Even though there has not been significant interest in terms of purchasing equipment that operates at the 0.4m2 scale, it does not beg off the issue of where we ultimately need to operate. This question has been clearly answered and it is one area where many precision agricultural teams have simply missed the mark in terms of doing what is right versus doing what is possible. We must continue to do what is right and to develop solutions to the problems that we know exist in the field.

Today, we can sense and fertilize every individual

corn plant on-the-go, using GreenSeeker NDVI sensors. The need for

having this kind of accuracy at very small scales is clearly illustrated

in the corn photos, and graphs below

Today, we can sense and fertilize every individual

corn plant on-the-go, using GreenSeeker NDVI sensors. The need for

having this kind of accuracy at very small scales is clearly illustrated

in the corn photos, and graphs below