|

Hand Planter Video

NEWS |

Ebb and Flow Video (best pace for planting)

Oklahoma State University Hand Planter Manual bill.raun@okstate.edu |

||||||||||||||||||||||||||||||||||||

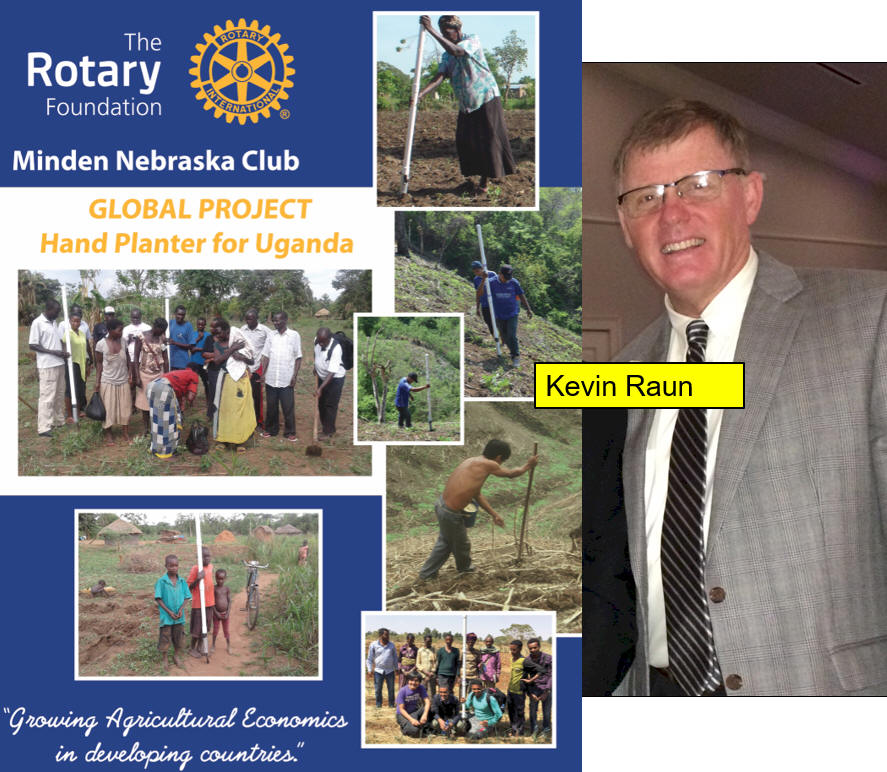

Minden Rotary Club, Minden Rotary Club,

abc TV Coverage Valerie Juarez |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

Hand Planters and Drums OVER THE YEARS

|

|||||||||||||||||||||||||||||||||||||

Labor Savings Video (17 Mb) 938/1/05, 1065/1/19, 1185/1/29, 1343/2/12, 1599/3/1, 1798/3/14, 2227/4/5 |

|||||||||||||||||||||||||||||||||||||

| Interview, Dr. Lisa Taylor and Peter Omara (Gulu University, Uganda) 12/15/2015 | |||||||||||||||||||||||||||||||||||||

| One Acre Fund | |||||||||||||||||||||||||||||||||||||

PLANTER User Manual (Spanish) |

|||||||||||||||||||||||||||||||||||||

| PDF version of Article | |||||||||||||||||||||||||||||||||||||

| http://smallfarmtoolbox.com/thegreenseeder | |||||||||||||||||||||||||||||||||||||

| Countries where the OSU Hand Planter is being used, (Pictures and Progress) | |||||||||||||||||||||||||||||||||||||

| Power point presentations | |||||||||||||||||||||||||||||||||||||

| Odyssey_misses | |||||||||||||||||||||||||||||||||||||

| (workshop data base) | |||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||

|

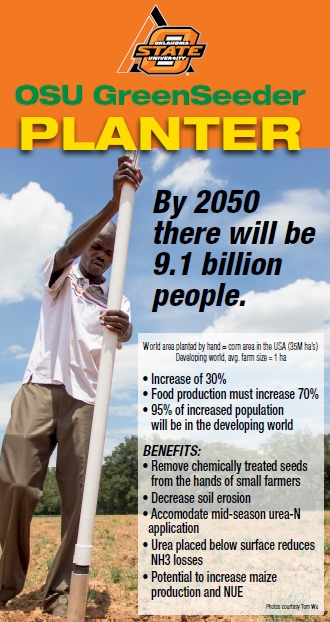

We have developed a hand planter very similar in shape, size, and weight to the one seen in the first photograph on our web site, but that can reliably plant 1 seed, in various soil textures, moisture, and tillage systems. Initially, development, production, and delivery would need to be subsidized, thus the need for grant funds. But with time, local manufacture/industry creation of our new hand planter would also lead to more jobs. Added benefits of the new hand planter would be to remove chemically treated seeds (organophosphates, carbamates, chlordanes, +others) from the hands of small farmers. Decreased soil erosion from improved contour planting, and plant proximity will also be achieved. With time, we hope to modify the final prototype so as to accommodate mid season applications of urea fertilizer. Placing urea fertilizer below the surface, really via any mechanism is critical for improved nitrogen use efficiency. This tool by itself would offer an affordable, easily adoptable technology for virtually all third world maize farmers. With modest funding for development and initial subsidized hand planters, this could provide widespread increases in third-world maize production that would rival most advances made in the last 50 years. CIMMYT mega-environment database; C.R. Dowswell, R.L. Paliwal and R.P. Cantrell, Maize in the Third World, Boulder, Colorado, Westview Press, 1996. |

|||||||||||||||||||||||||||||||||||||

|

"You cannot build a peaceful world on empty stomachs and human misery" Norman Borlaug Nobel Peace Prize Laureate, 1970 |

|||||||||||||||||||||||||||||||||||||

| Hand Planter Cooperation | |||||||||||||||||||||||||||||||||||||

|

Assoumane Maiga, Mali Representative Argemiro Moreno, Colombia RepresentativeAGCO Dupont-Pioneer CIMMYT - Asia CIMMYT - Africa CENTA, CARE, El Salvador Sierra Leone Kenya Ethiopia Uganda Zimbabwe India China Mexico Central America (all NARS) IPNI, Armando Tasistro Sierra Leone (Pat Bell) NGO's (several) |

|||||||||||||||||||||||||||||||||||||

| Regional Trials (proposal) | |||||||||||||||||||||||||||||||||||||

|

IMG_0901.MOV

IMG_0903.MOV |

|||||||||||||||||||||||||||||||||||||

| Hand Planter Release in Cali, Colombia, February 5, 2013 | |||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| Hand Planters Shipped to El Salvador, Guatemala, and Thailand, April 29, 2013 | |||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| Background Data | |||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

Source: CIMMYT mega-environment database; C.R. Dowswell, R.L. Paliwal and R.P. Cantrell, Maize in the Third World, Boulder, Colorado, Westview Press, 1996. |

|||||||||||||||||||||||||||||||||||||

|

Students: Adrian Koller, Eric Lam, Joshua Ringer Peter Omara, Fikayo Oyebiyi, Eva Nambi, Lawrence Aula, Sulochana Dhital, Ethan Wyatt, Natasha Macnack, Jeremiah Mullock, Jacob Bushong, Bee Chim, Eric Miller, Candi Byani, Jorge Rascon, Max Metcalf, Kyle Hiner, Jonathan Kelly, Kevin Waldschmidt Ideas proposed in May, 2007. Meetings: Wednesday, 4:00 pm, Ag Engineering Shop Energy Harvesting for Singulation (A. Koller and J. Rascon) |

|||||||||||||||||||||||||||||||||||||

| Planning | |||||||||||||||||||||||||||||||||||||

|

OSU Hand Planter Plan

2009 AGCO Hand Planter Demo Report |

|||||||||||||||||||||||||||||||||||||

| Added Materials | |||||||||||||||||||||||||||||||||||||

IDEAS: www.crustbuster.com (wobble slot) |

|||||||||||||||||||||||||||||||||||||

|

Could these planters work using a protective rubber glove? Yes, but, the problem is that producers will not wear the gloves because they rely on finger dexterity and sensing to feel individual seeds. At the end of the day they have imbibed chemicals via skin to chemical surface contact.

https://www.youtube.com/watch?v=zc3DN0tokUQ https://www.youtube.com/watch?v=RlpOy7lgXmU OSU is aware of these planters and that have been discussed. The problem (demonstrated in the first video), is that they won’t wear the latex/rubber gloves. In most parts of the world, it is hot and humid, at the time of “hand planting”. As such, the human element of being able to singulate (using their fingers, and sensitivity in their fingers), relies on “not having gloves on.” Are they (the producers) aware of the chemical contamination risks? Some are. So, because OSU is well aware, we think they need a hand planter makes that makes the decision for them. Marv Stone showed us a patent from Dickey-John that was older, but that recognized each seed (counted them as they passed by x-sensor). |

|||||||||||||||||||||||||||||||||||||

|

Chinese farmers currently feed 20% of the global population using only 9% of

the world’s arable land. Their traditional corn farming technique —

involving planting two to three kernels of corn per mound of soil just to

get one plant to grow — highlighted a need for a more efficient planting

technology. While this technique may have improved the odds, it had a habit

of creating high seed and labor costs. Which is why in 2002, DuPont Pioneer

entered the

Quick Facts 33%

of wasted corn plants could be saved with vacuum planting.

Planting better seeds, in a smarter way.

Pioneer partnered with Hebei Nonghaha Agricultural Machinery Group, a local

equipment manufacturer, to jointly develop a vacuum planter — the first of

its kind in the country — that would allow Chinese farmers to plant corn

using only one seed per mound. Improved single kernel planting technology

raises the productivity and efficiency of Pioneer’s corn, lowers the seed

volume farmers need to purchase, reduces manual labor, and ensures more land

can be used for other products, like grain, diversifying and increasing the

area’s food production output.

So far, it’s working — single kernel planting is becoming a trend in China,

and if the vacuum planter continues to be widely adopted, it’s estimated

that 1/3 of corn plants wasted by the manual thinning process could be

saved. Additionally, |

|||||||||||||||||||||||||||||||||||||

| Last update: March 19, 2021 | |||||||||||||||||||||||||||||||||||||

| NEW Hand Planter Video, online | |||||||||||||||||||||||||||||||||||||